- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China PCB and PCBA Service One Stop Electronic PCB Service Manufacturers, Suppliers, Factory

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for PCB and PCBA Service One Stop Electronic PCB Service,PCBA Electronic,PCB Electronic,One Stop Electronic PCB Assembly Service,PCB PCBA Service One Stop Electronic Service, Never-ending improvement and striving for 0% deficiency are our two main good quality policies. Should you need anything, do not hesitate to call us.

PCB and PCBA Service One Stop Electronic PCB Service, To create more creative products and solutions, maintain high-quality goods and update not only our products and solutions but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we present and to grow stronger together. To be the real winner, starts here!

Hot Products

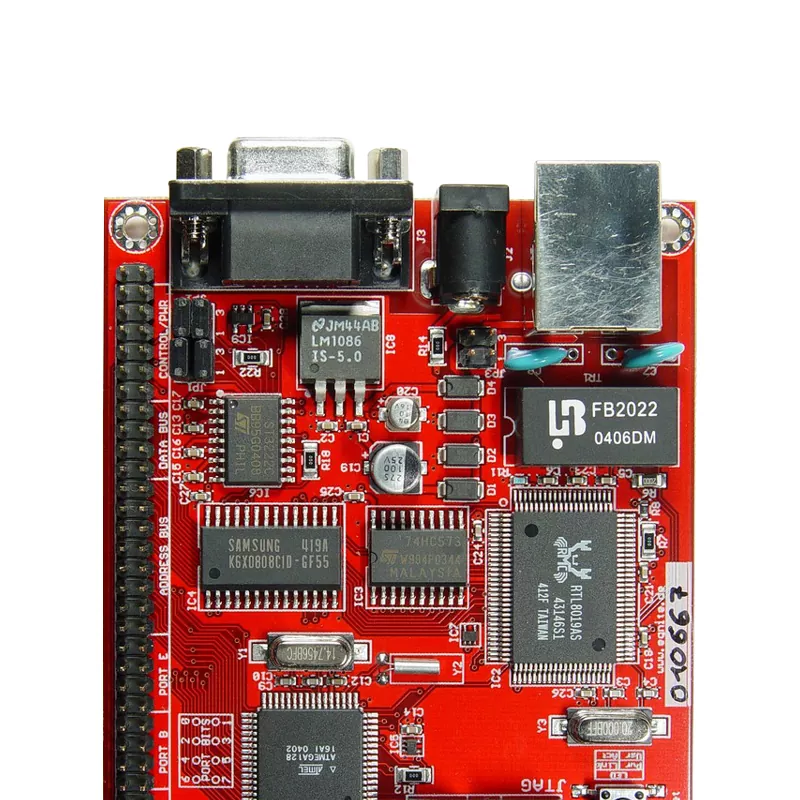

Controller PCBA Board Assembly

Controller PCBA Board Assembly: Streamline Your Electronic Device Production Electronic devices that require controllers are ubiquitous and are used in a wide range of applications, including industrial automation, robotics, and consumer electronics. In order to ensure that these devices function smoothly and efficiently, it's important to have a high-quality controller PCB assembly (PCBA) in place. This is where our controller PCBA board assembly service comes in.PCBA Solder Paste Inspection

Hitech is a professional China PCBA Solder Paste Inspection manufacturer and supplier, Printed Circuit Board Assembly (PCBA) refers to the process of assembling electronic components onto a printed circuit board (PCB). A PCB is an electronic component that consists of conductive pathways, electronic components, and other elements assembled on a non-conductive substrate using printing techniques. PCBA involves soldering electronic components onto the PCB to complete the assembly and connection of circuits.Reflow Soldering PCB Assembly

Hitech is a professional leader China Reflow Soldering PCB Assembly manufacturer with high quality and reasonable price. It is a method used to join the surface mount components to the PCB using solder paste. Reflow soldering involves heating the PCB assembly to a specific temperature, melting the solder paste and creating a permanent joint between the component and the PCB. The process is highly precise, allowing for the creation of high-quality and reliable PCBAs that are used in a wide range of electronic devices. Reflow soldering is a key element in the manufacturing process of PCBAs, ensuring that the final product is of high quality, free from defects, and functions as intended.FR4 PCB

FR4 PCBs (Printed Circuit Boards) are one of the most widely used types of PCBs in the electronics industry. They are made from a material called FR4, which is a type of glass-reinforced epoxy laminate. FR4 is known for its excellent electrical insulation properties, high strength, and resistance to heat and moisture. These properties make FR4 PCBs an ideal choice for a wide range of applications, including consumer electronics, medical devices, industrial equipment, and more.PCBA Design

In today's fast-paced technological landscape, the success of any electronic device hinges on its Printed Circuit Board Assembly (PCBA) design. A flawless PCBA design not only ensures optimal performance but also enables innovation, efficiency, and cost-effectiveness. In this article, we will delve into the world of PCBA design, exploring its importance, key considerations, and the benefits it brings to product development. Whether you are an electronics enthusiast or a seasoned professional, read on to unlock the secrets of PCBA design.Box Build

Hitech is China manufacturer & supplier who mainly produces Box Build with many years of experience. Hope to build business relationship with you.