- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

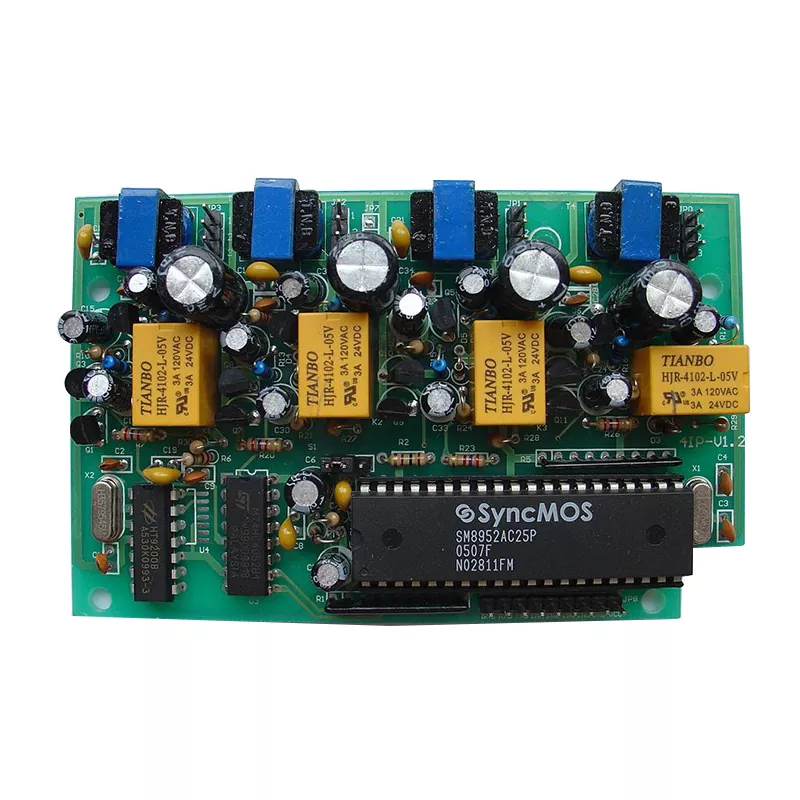

China One Stop Electronic PCB Assembly Service Manufacturers, Suppliers, Factory

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for One Stop Electronic PCB Assembly Service,PCBA Electronic,PCB Electronic,PCB and PCBA Service One Stop Electronic PCB Service,PCB PCBA Service One Stop Electronic Service, We often concertrating on creating new creative solution to meet request from our customers everywhere in the planet. Sign up for us and let's make driving safer and funnier with each other!

One Stop Electronic PCB Assembly Service, Welcome to visit our company, factory and our showroom where displays various hair solutions that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to deliver you the best service. Be sure to contact us if you want more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

Hot Products

QFN PCB Assembly

The Future of High-Density Electronics The electronics industry is constantly evolving, with new technologies and innovations emerging every day. One of the latest trends in high-density electronics is the use of QFN (Quad Flat No-Lead) packages. These packages allow for a higher density of components on the PCB, resulting in smaller and more efficient electronic devices. At our company, we specialize in QFN PCB assembly services that cater to a wide range of industries.PCBA Automated Optical Inspection

Hitech as the professional manufacturer, we would like to provide you high quality PCBA Automated Optical Inspection. PCBA Automated Optical Inspection (AOI) is a technology used in the manufacturing process of Printed Circuit Board Assemblies to automatically inspect and identify defects or anomalies in the soldering and component placement.Electronic Manufacturing Service

Electronic Manufacturing Service (EMS) is a complete solution for outsourcing the manufacturing of electronic products. This service includes a range of activities, from design and prototyping to final assembly, testing, and shipping. EMS providers work with original equipment manufacturers (OEMs) and other companies to provide a one-stop-shop for the entire electronics manufacturing process.IOT PCB design and manufacturing

Find a huge selection of IOT PCB design and manufacturing from China at Hitech. Provide professional after-sales service and the right price, looking forward to cooperation.Bluetooth Tracker PCBA Design

One of Chinese manufacturer of Bluetooth Tracker PCBA Design, offering excellent quality at a competitive price, is Hitech. Feel free to get in touch.LED PCBA Board

Hitech is one of professional leader China LED PCBA board manufacturer with high quality and reasonable price. Welcome to contact us.