- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Injection Molding-Blow Molding Plastic Manufacturers, Suppliers, Factory

Each individual member from our significant effectiveness gross sales workforce values customers' demands and small business communication for Injection Molding-Blow Molding Plastic,Metal Injection Molding Prototype,Concrete Injection Molding Part,Largest Injection Molding,Foam Injection Molding Short Shot, We hope we can have a friendly relationship with businessman from all over the world.

Injection Molding-Blow Molding Plastic, In order to meet our market demands, we now have paied more attention to the quality of our products and solutions and services. Now we can meet customers' special requirements for special designs. We persistently develop our enterprise spirit "quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

Hot Products

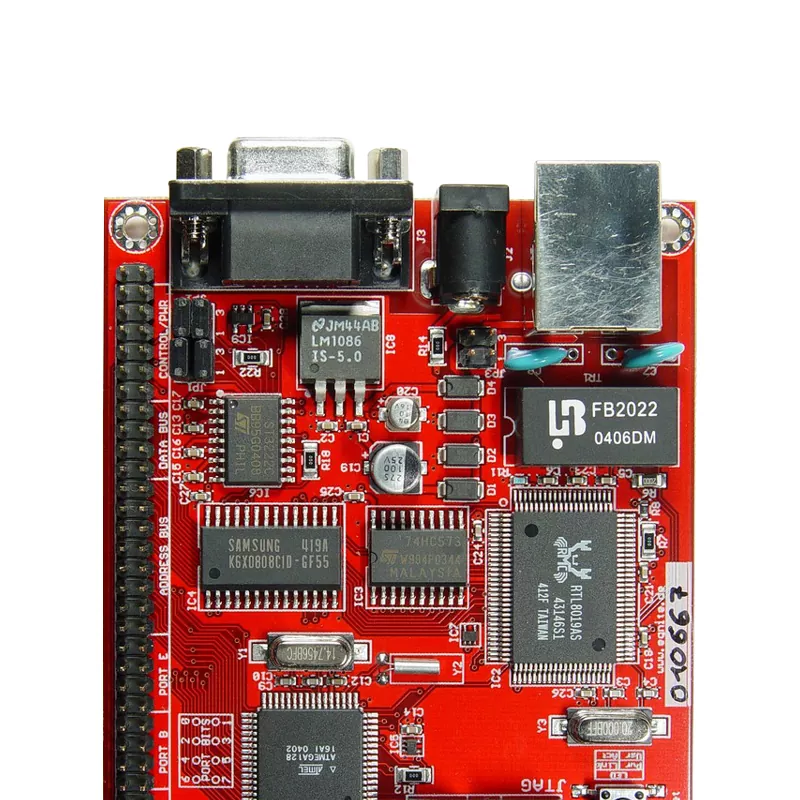

Medical PCBA Board

Hitech is Medical PCBA Board manufacturers and suppliers in China who can wholesale Medical PCBA Board. Printed Circuit Board Assemblies (PCBAs) have become an essential component in the manufacturing of medical devices. They play a vital role in the functioning of medical equipment by providing a reliable and efficient means of controlling various processes and functions. In the medical industry, PCBAs are used in a wide range of applications, from monitoring and diagnostic equipment to surgical instruments and implantable devices.DIP PCB Assembly

Hi Tech is a professional DIP PCB Assembly manufacturer and supplier in China. We have produced DIP PCB Assembly for many years. At Hi Tech, we specialize in providing high-quality DIP PCB assembly services to customers around the world. With years of experience in the industry, we have built a reputation for excellence in terms of both quality and customer service.FR4 PCB

FR4 PCBs (Printed Circuit Boards) are one of the most widely used types of PCBs in the electronics industry. They are made from a material called FR4, which is a type of glass-reinforced epoxy laminate. FR4 is known for its excellent electrical insulation properties, high strength, and resistance to heat and moisture. These properties make FR4 PCBs an ideal choice for a wide range of applications, including consumer electronics, medical devices, industrial equipment, and more.PCBA Prototype

Hitech is a professional PCBA Prototype manufacturers and suppliers in China.PCBA prototype is a crucial step in the electronic design process. It involves creating a functional electronic circuit using a prototype PCB and assembling the components onto the PCB to test and validate the design. The PCBA prototype process is essential to ensure the success of your electronic product, and in this article, we will explore the importance of PCBA prototype and the factors to consider when creating a PCBA prototype.Rigid-Flexible PCB

As the professional manufacture, Hitech would like to provide you Rigid-Flexible PCB. A rigid-flexible PCB is a printed circuit board that combines both rigid and flexible materials in a single board. Rigid-flex PCBs are designed to provide the benefits of both rigid and flexible PCBs, allowing for greater design flexibility and functionality.LED PCBA Board

Hitech is one of professional leader China LED PCBA board manufacturer with high quality and reasonable price. Welcome to contact us.