- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

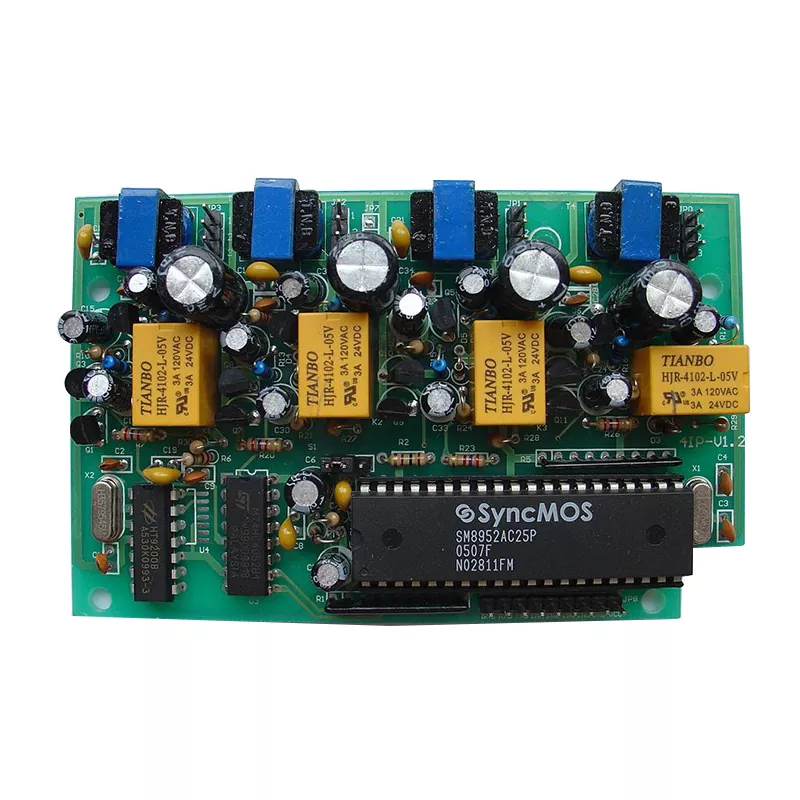

China Shenzhen Electronic Box Build Assembly Manufacturers, Suppliers, Factory

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, belief the very first and management the advanced" for Shenzhen Electronic Box Build Assembly,Magnetic Shuttering Formwork Concrete Magnet Box,Electronics Assembly and Shenzhen Box Build,Assembly Box Build Contract Manufacturing,Robot Cable Wiring Harnesses Assembly and Box Build, Our staff members are goal to provides solutions with high performance cost ratio to our prospects, as well as target for all of us is always to satisfy our consumers from everywhere in the globe.

Shenzhen Electronic Box Build Assembly, In the increasingly competitive market, With sincere service high quality products and well-deserved reputation, we always supply customers support on solutions and techniques to achieve long-term cooperation. Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we will become long-term partners.

Hot Products

Hardware Injection Molding

Hitech warmly welcome you to wholesale Hardware Injection Molding from our factory. Hardware Injection Molding is a manufacturing process that is used to produce a wide variety of hardware components such as screws, nuts, bolts, washers, and other small metal parts. This process involves using a plastic injection molding machine to melt metal pellets or granules and inject them into a mold under high pressure and temperature. Once the metal cools and solidifies, the mold is opened, and the finished part is ejected.Rigid-Flexible PCB

As the professional manufacture, Hitech would like to provide you Rigid-Flexible PCB. A rigid-flexible PCB is a printed circuit board that combines both rigid and flexible materials in a single board. Rigid-flex PCBs are designed to provide the benefits of both rigid and flexible PCBs, allowing for greater design flexibility and functionality.Box Build

Hitech is China manufacturer & supplier who mainly produces Box Build with many years of experience. Hope to build business relationship with you.Injection Molding

material into a mold to create a wide variety of plastic parts. At our injection molding facility, we have the expertise and technology to produce high-quality, custom plastic parts for a range of industries, including automotive, aerospace, medical, and consumer goods.Customized PCB Assembly

As one of professional manufacturer in China, Hitech would like to provide you Customized PCB Assembly. And we will offer you the best after-sale service and timely delivery.Custom Charging PCBA

In today's fast-paced world, the need for efficient and reliable power supply for electronic devices makes high-performance charging solutions essential. To meet the growing demand for customizable, high-performance charging, innovations in the HiTech field have led to the development of custom charging PCBA. These specialized printed circuit board assemblies are designed to deliver performance exceeding that of standard solutions.