- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Injection Molding Machine Manufacturers, Suppliers, Factory

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, belief the very first and management the advanced" for Injection Molding Machine,Metal Injection Molding Prototype,Concrete Injection Molding Part,Largest Injection Molding,Foam Injection Molding Short Shot, Our staff members are goal to provides solutions with high performance cost ratio to our prospects, as well as target for all of us is always to satisfy our consumers from everywhere in the globe.

Injection Molding Machine, All styles appear on our website are for customizing. We meet up to individual requirements with all solutions of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

Hot Products

Reflow Soldering PCB Assembly

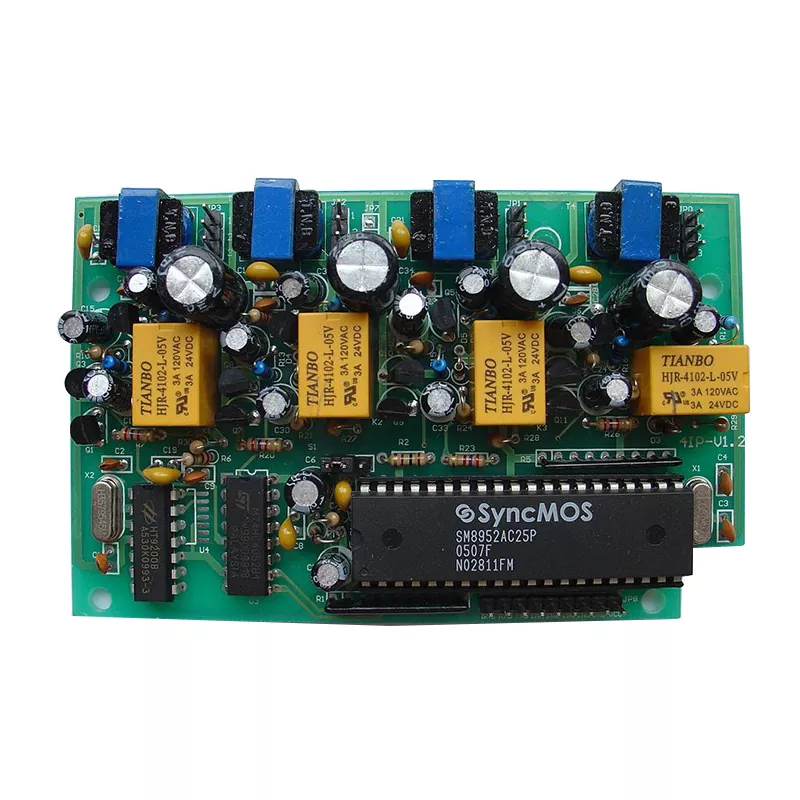

Hitech is a professional leader China Reflow Soldering PCB Assembly manufacturer with high quality and reasonable price. It is a method used to join the surface mount components to the PCB using solder paste. Reflow soldering involves heating the PCB assembly to a specific temperature, melting the solder paste and creating a permanent joint between the component and the PCB. The process is highly precise, allowing for the creation of high-quality and reliable PCBAs that are used in a wide range of electronic devices. Reflow soldering is a key element in the manufacturing process of PCBAs, ensuring that the final product is of high quality, free from defects, and functions as intended.Pcba Function Testing

Printed Circuit Board Assemblies (PCBAs) are essential components in the manufacturing of electronic devices. They are used in a wide range of products, from consumer electronics to industrial equipment. PCBAs need to be reliable and perform as intended to ensure the functionality of the final product. That's where PCBA function testing comes in.Power PCBA Board Assembly

Welcome to buy Power PCBA Board Assembly from Hitech.A power PCBA board is a printed circuit board assembly (PCBA) that is specifically designed and optimized for power management and distribution. Power PCBA boards are used in a variety of applications where high levels of power need to be managed and distributed efficiently and effectively.Bluetooth Tracker PCBA Design

One of Chinese manufacturer of Bluetooth Tracker PCBA Design, offering excellent quality at a competitive price, is Hitech. Feel free to get in touch.Conformal coating

Conformal coating is a protective coating applied to assembled printed circuit boards (PCBs) and electronic components to prevent damage from moisture, dust, temperature variations, and other environmental factors.Power Supply PCBA

With the continuous evolution of modern electronic products, a stable and reliable power supply is crucial for ensuring the long-term, efficient operation of these devices. Hitech's professionally designed and manufactured Power Supply PCBA (printed circuit board assemblies) are designed to meet this core requirement. Our factory, with its precise design, rigorous component selection, and advanced manufacturing processes, provides a solid and stable power foundation for numerous original equipment manufacturers (OEM) and electronics manufacturers, ensuring their end products deliver superior performance and long-lasting durability.