- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Products

- View as

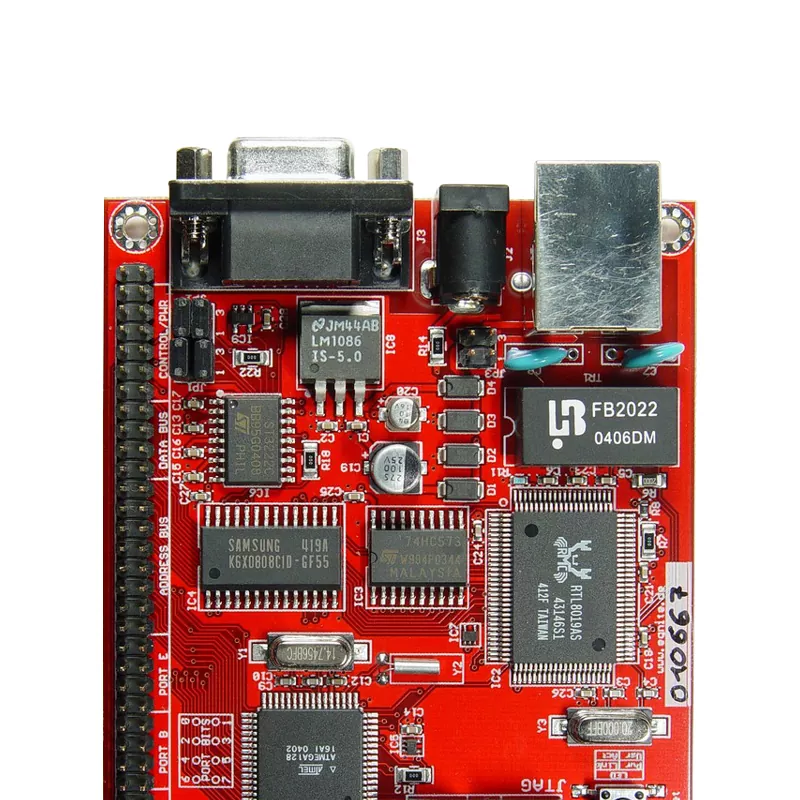

PCB Schematic Design

PCB schematic design is a critical aspect of the electronic design process, and it is essential to get it right to ensure the success of your project. PCB schematic design is the process of creating a graphical representation of the electronic circuitry that will be implemented on the PCB. This graphical representation is used to guide the layout and routing of the PCB, ensuring that the final product meets the desired requirements and specifications.

Read MoreSend InquiryMultilayer PCB

Multilayer PCBs (Printed Circuit Boards) are a highly advanced and versatile type of PCB used in a wide range of industries, from consumer electronics to aerospace. They are designed with multiple layers of conductive copper traces and insulating material, providing a high level of complexity and functionality in a single PCB. Multilayer PCBs offer a wide range of benefits, making them an ideal choice for advanced electronic devices.

Read MoreSend InquiryFR4 PCB

FR4 PCBs (Printed Circuit Boards) are one of the most widely used types of PCBs in the electronics industry. They are made from a material called FR4, which is a type of glass-reinforced epoxy laminate. FR4 is known for its excellent electrical insulation properties, high strength, and resistance to heat and moisture. These properties make FR4 PCBs an ideal choice for a wide range of applications, including consumer electronics, medical devices, industrial equipment, and more.

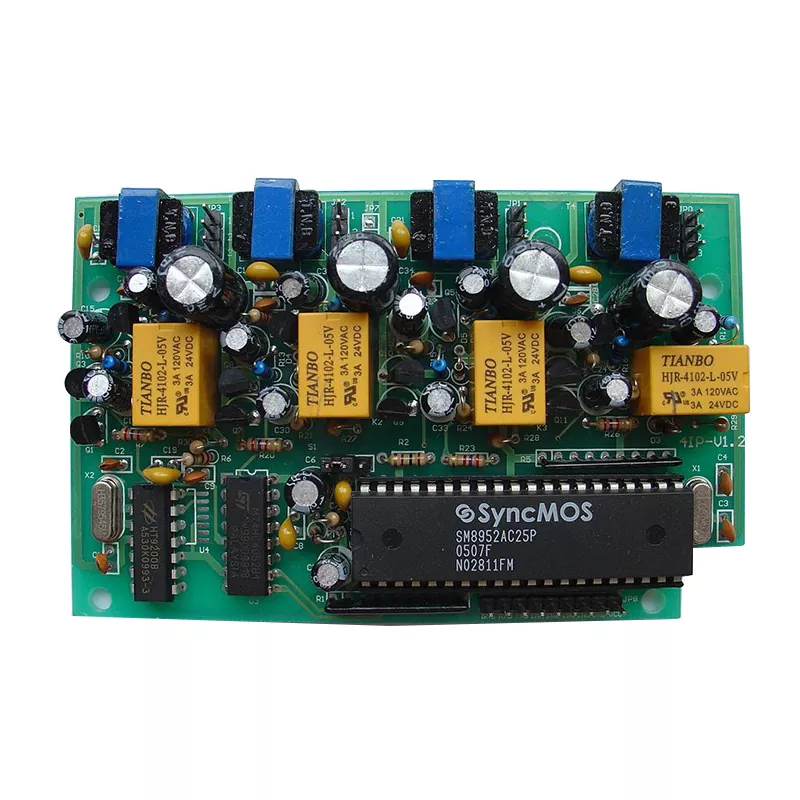

Read MoreSend InquiryPcba Function Testing

Printed Circuit Board Assemblies (PCBAs) are essential components in the manufacturing of electronic devices. They are used in a wide range of products, from consumer electronics to industrial equipment. PCBAs need to be reliable and perform as intended to ensure the functionality of the final product. That's where PCBA function testing comes in.

Read MoreSend InquiryWave Soldering PCB Assembly

Wave Soldering PCB Assembly is another method used in the manufacturing of Printed Circuit Board Assemblies (PCBAs). It is a through-hole soldering process that involves passing the PCB assembly over a wave of molten solder. The process is used to create a permanent joint between the through-hole components and the PCB. The wave of molten solder is created by heating a pot of solder to a specific temperature, then pumping the solder over a wave generator. The PCB assembly is then passed over the wave, which coats the through-hole components in solder, creating a permanent joint.

Read MoreSend InquiryReflow Soldering PCB Assembly

Hitech is a professional leader China Reflow Soldering PCB Assembly manufacturer with high quality and reasonable price. It is a method used to join the surface mount components to the PCB using solder paste. Reflow soldering involves heating the PCB assembly to a specific temperature, melting the solder paste and creating a permanent joint between the component and the PCB. The process is highly precise, allowing for the creation of high-quality and reliable PCBAs that are used in a wide range of electronic devices. Reflow soldering is a key element in the manufacturing process of PCBAs, ensuring that the final product is of high quality, free from defects, and functions as intended.

Read MoreSend Inquiry