- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China SMT PCB Assembly Manufacturers, Suppliers, Factory

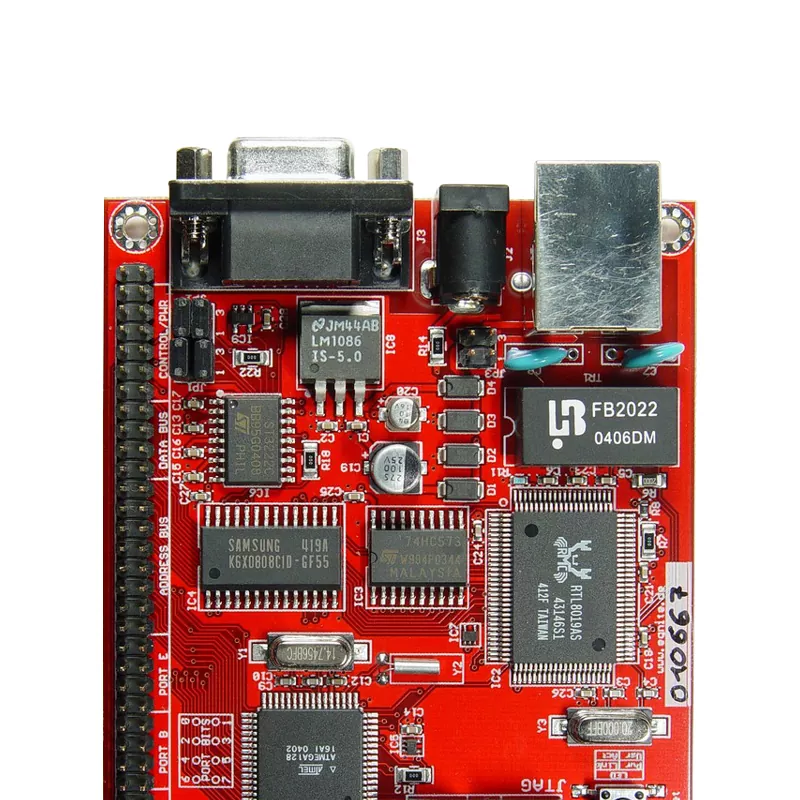

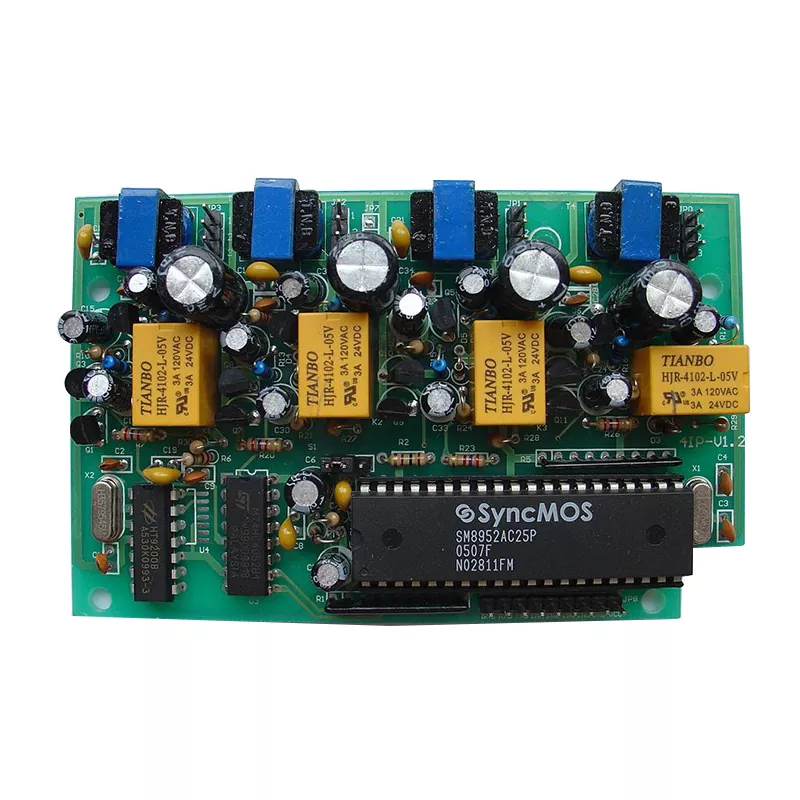

Hitech is one of the famous China SMT PCB Assembly manufacturers and SMT PCB Assembly suppliers. AtHi Tech PCB Assembly, we understand that when it comes to manufacturing electronic devices, you need a reliable partner that can deliver high-quality PCBAs quickly and efficiently. That's why we offer advanced PCBA SMT assembly services that are designed to meet the unique needs of your business.

we utilize the latest in SMT (Surface Mount Technology) assembly equipment and techniques to ensure that your PCBs are assembled with precision and accuracy. This allows us to deliver fast turnaround times without sacrificing quality, so you can get your products to market faster.

Our PCBA SMT assembly services include:

Automated SMT Assembly: Ouradvanced equipment allows us to automate the SMT assembly process, reducing the risk of errors and increasing efficiency.

High-Speed Pick and Place Machines: Our high-speed pick and place machines allow us to place components on your PCBs quickly and accurately, reducing assembly time and costs.

Advanced Reflow Ovens: Our advanced reflow ovens ensure that your PCBs are heated to the optimal temperature, resulting in strong, reliable solder joints.

In-House Testing: We perform rigorous testing on all of our PCBAs to ensure that they meet our high standards for quality and performance.

AtHi Tech PCB Assembly, we are committed to providing our customers with a seamless and hassle-free experience. Our team of experienced engineers and technicians are dedicated to delivering exceptional customer service, and we work closely with our clients to ensure that their specific needs and requirements are met.

Whether you are looking to bring a new product to market or need to scale up your production,Hi Tech PCB Assembly has the expertise and resources to help you succeed. Contact us today to learn more about our PCBA SMT assembly services and how we can help take your business to the next level.

- View as

Remote PCBA

Hitech, a reputable manufacturer in China, is willing to offer you Remote PCBA. We promise to provide you with the best after-sale support and prompt delivery.

Read MoreSend InquiryLED PCBA Board Design

Hitech invites you to visit our factory to purchase the newest, best-selling, affordable, and high-quality LED PCBA Board Design. We are looking forward to working with you.

Read MoreSend InquiryLED PCBA Board

Hitech is one of professional leader China LED PCBA board manufacturer with high quality and reasonable price. Welcome to contact us.

Read MoreSend InquiryPCB Assembly Process

Hitech is China manufacturer & supplier who mainly produces PCB Assembly Process with many years of experience. Hope to build business relationship with you.

Read MoreSend InquiryFR4 PCB

FR4 PCBs (Printed Circuit Boards) are one of the most widely used types of PCBs in the electronics industry. They are made from a material called FR4, which is a type of glass-reinforced epoxy laminate. FR4 is known for its excellent electrical insulation properties, high strength, and resistance to heat and moisture. These properties make FR4 PCBs an ideal choice for a wide range of applications, including consumer electronics, medical devices, industrial equipment, and more.

Read MoreSend InquiryPcba Function Testing

Printed Circuit Board Assemblies (PCBAs) are essential components in the manufacturing of electronic devices. They are used in a wide range of products, from consumer electronics to industrial equipment. PCBAs need to be reliable and perform as intended to ensure the functionality of the final product. That's where PCBA function testing comes in.

Read MoreSend Inquiry