- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Injection Molding Blow Molding Part Manufacturers, Suppliers, Factory

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Injection Molding Blow Molding Part,Metal Injection Molding Prototype,Concrete Injection Molding Part,Largest Injection Molding,Foam Injection Molding Short Shot, We normally welcome new and outdated customers presents us with worthwhile advice and proposals for cooperation, allow us to develop and acquire jointly, also to contribute to our local community and staff!

Injection Molding Blow Molding Part, By continuous innovation, we will supply you with more valuable merchandise and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

Hot Products

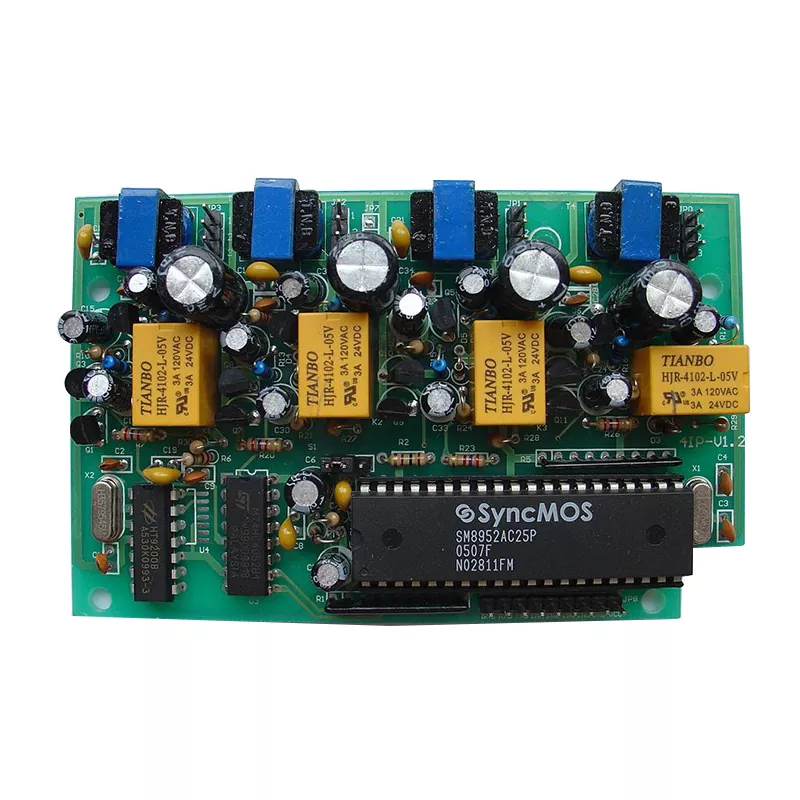

Rigid-Flexible PCB

As the professional manufacture, Hitech would like to provide you Rigid-Flexible PCB. A rigid-flexible PCB is a printed circuit board that combines both rigid and flexible materials in a single board. Rigid-flex PCBs are designed to provide the benefits of both rigid and flexible PCBs, allowing for greater design flexibility and functionality.Bluetooth Tracker PCBA Design

One of Chinese manufacturer of Bluetooth Tracker PCBA Design, offering excellent quality at a competitive price, is Hitech. Feel free to get in touch.IOT PCB Design And Layout

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality IOT PCB design and layout, Hitech looks forward to cooperating with you.Conformal coating

Conformal coating is a protective coating applied to assembled printed circuit boards (PCBs) and electronic components to prevent damage from moisture, dust, temperature variations, and other environmental factors.Introduction to Our Expertise in PCB Design

In today's rapidly advancing technological landscape, Printed Circuit Board (PCB) design plays a pivotal role in the development of modern electronics and systems. At our company, we pride ourselves as leaders in introduction to Our Expertise in PCB Design, a field that involves the strategic layout and assembly of electronic components on a flat surface to ensure optimal performance and functionality.Custom Charging PCBA

In today's fast-paced world, the need for efficient and reliable power supply for electronic devices makes high-performance charging solutions essential. To meet the growing demand for customizable, high-performance charging, innovations in the HiTech field have led to the development of custom charging PCBA. These specialized printed circuit board assemblies are designed to deliver performance exceeding that of standard solutions.