- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

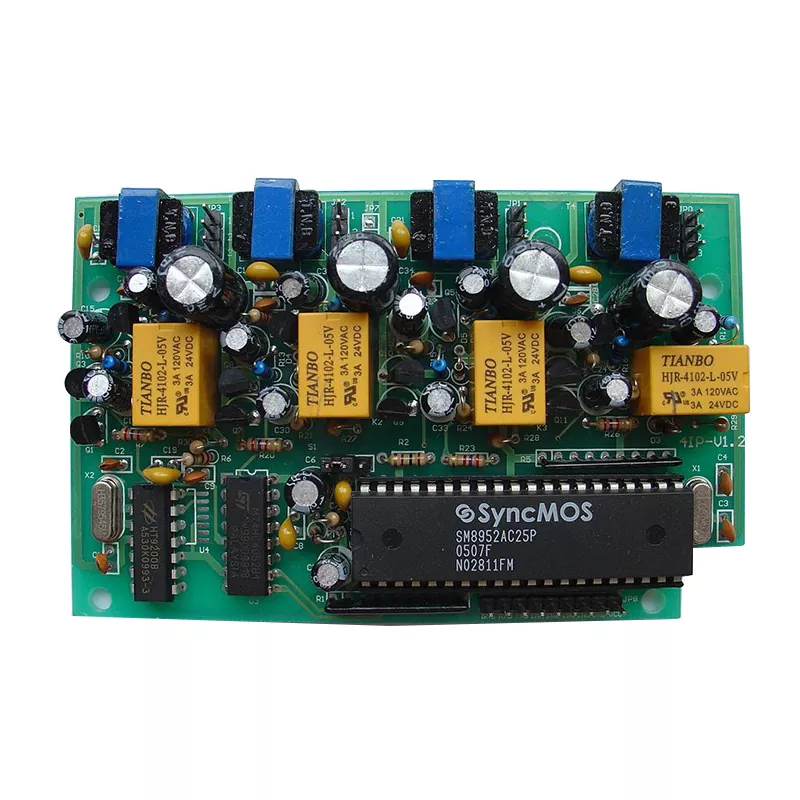

China PCB Assembly for Telecommunication Products and PCBA of Programming Manufacturers, Suppliers, Factory

The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for PCB Assembly for Telecommunication Products and PCBA of Programming,PCB Build PCBA Assembly Rigid Board Motherboard Programming Mainboard Assembly,Multi- Layers Circuit Boards Assembly PCBA with Sourcing, Manufacturing, Programming, Testing Service,PCBA Copy Clone with Decoding The IC Programming for PCB Board,Professional PCB Software Programming Circuit Board Solar Energy Board PCBA, To significantly improve our assistance quality, our company imports a large number of international advanced devices. Welcome clients from your home and abroad to simply call and inquire!

PCB Assembly for Telecommunication Products and PCBA of Programming, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The items are obtainable in improved designs and richer variety, they're produced scientifically of purely raw sup+C7plies. It accessible in a variety of designs and specs for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

Hot Products

Pcba Function Testing

Printed Circuit Board Assemblies (PCBAs) are essential components in the manufacturing of electronic devices. They are used in a wide range of products, from consumer electronics to industrial equipment. PCBAs need to be reliable and perform as intended to ensure the functionality of the final product. That's where PCBA function testing comes in.Multilayer PCB

Multilayer PCBs (Printed Circuit Boards) are a highly advanced and versatile type of PCB used in a wide range of industries, from consumer electronics to aerospace. They are designed with multiple layers of conductive copper traces and insulating material, providing a high level of complexity and functionality in a single PCB. Multilayer PCBs offer a wide range of benefits, making them an ideal choice for advanced electronic devices.PCBA Design

In today's fast-paced technological landscape, the success of any electronic device hinges on its Printed Circuit Board Assembly (PCBA) design. A flawless PCBA design not only ensures optimal performance but also enables innovation, efficiency, and cost-effectiveness. In this article, we will delve into the world of PCBA design, exploring its importance, key considerations, and the benefits it brings to product development. Whether you are an electronics enthusiast or a seasoned professional, read on to unlock the secrets of PCBA design.Power PCBA Board Assembly

Welcome to buy Power PCBA Board Assembly from Hitech.A power PCBA board is a printed circuit board assembly (PCBA) that is specifically designed and optimized for power management and distribution. Power PCBA boards are used in a variety of applications where high levels of power need to be managed and distributed efficiently and effectively.Electronic Manufacturing Service

Electronic Manufacturing Service (EMS) is a complete solution for outsourcing the manufacturing of electronic products. This service includes a range of activities, from design and prototyping to final assembly, testing, and shipping. EMS providers work with original equipment manufacturers (OEMs) and other companies to provide a one-stop-shop for the entire electronics manufacturing process.Conformal coating

Conformal coating is a protective coating applied to assembled printed circuit boards (PCBs) and electronic components to prevent damage from moisture, dust, temperature variations, and other environmental factors.